Ground-borne vibration (GBV) is a widespread and growing problem in our cities, with sources like rail and road traffic disrupting building performance and occupant comfort.

CALMFLOOR offers a powerful, non-intrusive solution that dramatically reduces these vibrations at floor level without structural changes. With that in mind, we’ve taken a closer look at GBV and what building stakeholders can do to tackle it – from the ground up.

What is ground-borne vibration?

Ground-borne vibration refers to low-frequency oscillations transmitted through the ground from sources such as underground and overground trains, road traffic and construction activities. In dense urban environments, GBV is widespread and often inescapable. One of the most disconcerting aspects of GBV is that its source is usually invisible within private or commercial buildings – yet its effects are persistent, intrusive and difficult to avoid.

The GBV problem is on the rise and more people, businesses and building owners are finding themselves impacted by vibration levels that are noticeable but costly and complex to deal with. Effective solutions have been limited – until now.

CALMFLOOR changes this landscape. As a mass-produced active mass damper, CALMFLOOR offers a practical, scalable and proven way to control ground-borne vibrations – simply, effectively and with minimal disruption.

The urban vibration challenge

In major cities like London, New York, Tokyo and Paris, tens of thousands of buildings are located either directly above or within 30–100 metres of underground rail infrastructure. Many experience noticeable ground-borne vibrations, particularly in the 3–30 Hz range – most evident at suspended floor levels. The scale of the issue is striking:

• In London, over 45% of buildings in the city centre are within 100 metres of a Tube line.

• In New York, roughly 30–40% of buildings in Midtown and Downtown Manhattan sit above or alongside subway tunnels.

• In Tokyo, one study found that perceptible vibration levels (>0.3 mm/s) were recorded in more than half of locations monitored within 20 metres of underground rail infrastructure.

• Modern cities depend on underground systems – tunnels, subways, deep foundations – but these same systems transmit vibrations into nearby structures. The result: discomfort for occupants, disruption to sensitive equipment, reduced tenant satisfaction and, ultimately, diminished asset value for affected buildings.

Standard remedial measures

Traditional GBV mitigation methods include:

• Isolating the source (e.g. floating slab track-beds in rail tunnels)

• Interrupting the transmission path (e.g. open or filled trenches, underground barriers)

• Isolating building foundations or structural columns

These solutions are often expensive, costing anywhere between 0.1% and 10% of total building value – particularly for vibration-sensitive facilities like labs, healthcare buildings or concert halls. Even with high investment, their effectiveness is generally limited to higher-frequency vibrations (above 15 Hz), leaving low-frequency GBV (3–15 Hz) largely unresolved.

The shaking floor phenomenon

Low-frequency ground-borne vibrations typically excite a building’s foundations and vertical elements, i.e. its columns and walls. These in turn transmit movement upward through the structure, causing suspended floors to vibrate. This phenomenon, known as structural base excitation, is well-documented in earthquakes but also occurs in response to everyday ground-borne vibrations.

If a suspended floor’s natural frequency aligns with the vibration of its supports, resonance can occur – amplifying motion much like a floor directly excited by machinery. In this case, the excitation force is created by the floor’s own mass reacting to the movement of its supports.

Adding columns to control ground-borne vibrations

One conventional solution to floor resonance is to increase stiffness by adding additional columns or walls. While effective in some cases, this comes at a cost: added structural elements often compromise floorplan flexibility, architectural intent, and usable space – particularly in premium commercial or laboratory environments.

CALMFLOOR offers a new and powerful alternative. Unlike columns, which increase stiffness and create physical obstruction, CALMFLOOR provides a damping force that counters vibration without altering the structural layout. It eliminates the need for complex foundation interventions, avoids the spatial impact of floor stiffening and bypasses the limitations of traditional tuned mass dampers, which can de-tune if building use changes or require complex support structures.

How CALMFLOOR reduces floor vibration

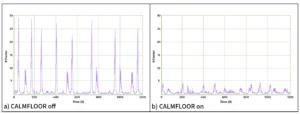

Figure 1a shows the measured vibration response of a suspended floor during a 20-minute monitoring period in which trains passed regularly beneath the building. With CALMFLOOR turned off, response factors reached levels of 23–30. In Figure 1b, taken under similar train activity with CALMFLOOR active, response levels dropped dramatically to 4–5.

Figure 1: Floor vibration response factors (1s RMS average) over two 20-minute periods with and without CALMFLOOR. The CALMFLOOR system reduces response factors from 23–30 to just 4–5—an outcome previously only achievable via major structural modification.

This substantial reduction was achieved with just a single CALMFLOOR unit, positioned at mid-span—where the floor’s modal response is most active and damping is most effective. In essence, CALMFLOOR behaves like an ‘invisible column’ that provides a reactive damping force, similar to a shock absorber, rather than adding stiffness. It controls the ‘offending’vibration mode at its peak without interfering with the floor’s structural design or intended use.

In this way, CALMFLOOR offers a transformative solution to ground-borne vibration: invisible, effective, and deployable at scale. For building owners, developers and engineers facing disruptive low-frequency vibration, it represents a powerful new tool to restore comfort, functionality and value – without compromise.

Book a demo