The solution

CALMFLOOR’s innovative technology is designed to deliver seamless, transformative vibration control in repurposed buildings, in this case, changing office space use into laboratory use, with significant improvements in vibration performance.

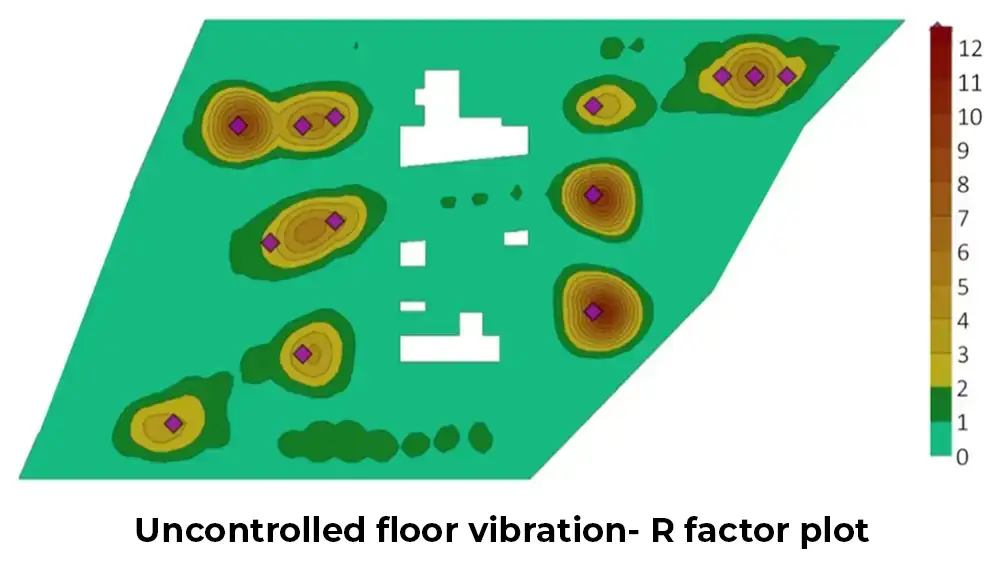

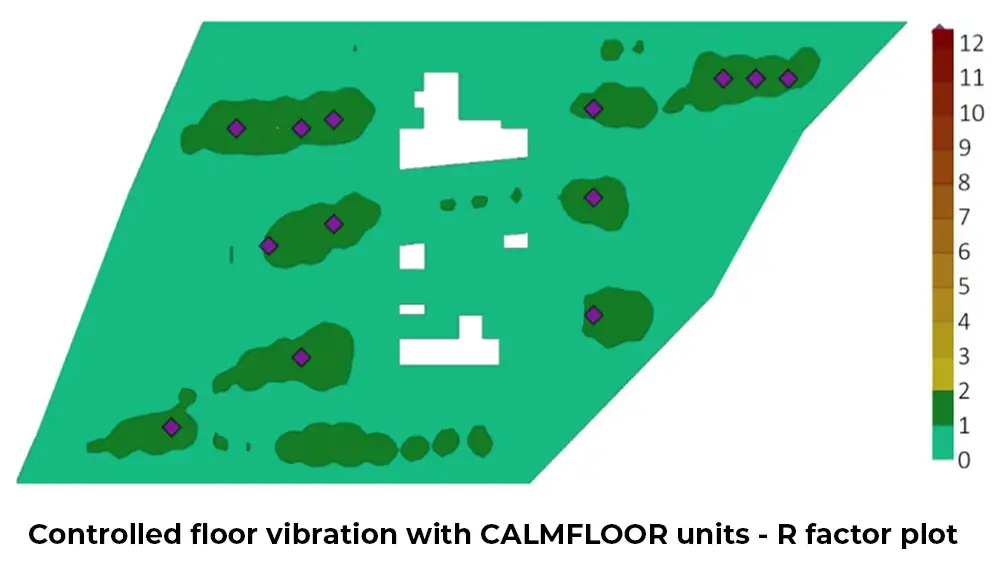

The image below illustrates how 13 CALMFLOOR units (shown as purple diamonds) strategically positioned across our customer’s floor would provide active vibration control. We showed how this technology would achieve a considerable reduction of almost 80% in response.

CALMFLOOR demonstrated huge potential for realising substantial reductions in both cost and embodied carbon to achieve vibration control in this repurposed building environment. Moreover, this elegant solution would upgrade the floor’s vibration performance to stringent, lab-quality performance criteria.