The solution

CALMFLOOR technology showed it would pave the way as a first-of-its-kind sustainable solution to significantly reduce floor weight and carbon footprint while meeting vibration performance. This seamless shift in design and material savings delivers remarkable improvements not only in vibration performance, but also in the potential for substantial carbon reductions.

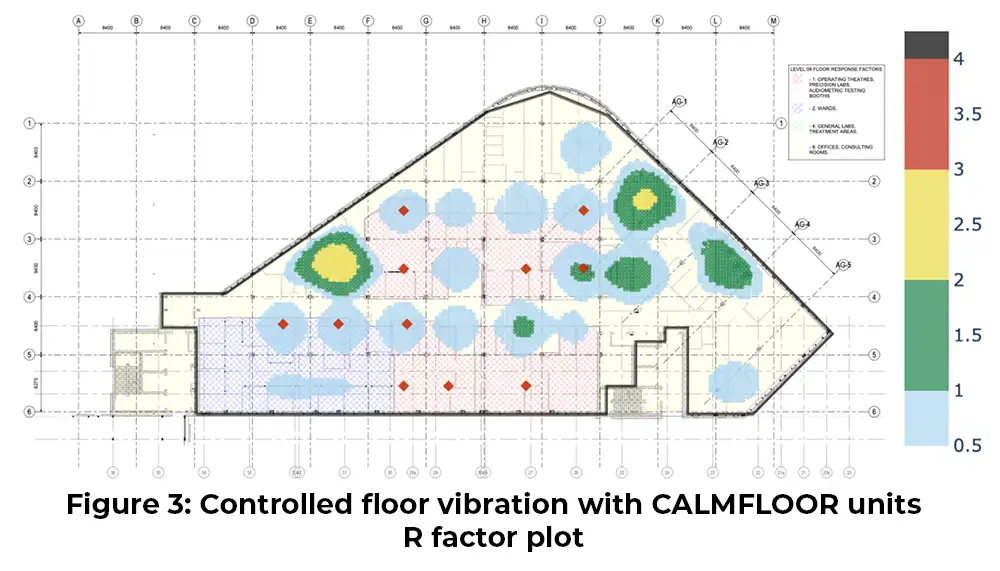

Figure 3 below illustrates the footfall analysis results following the adoption of seven strategic positions for the CALMFLOOR units that would deliver vibration control. This innovative technology facilitated an impressive reduction in embodied carbon and vibration responses.

We revealed considerable potential for achieving substantial reductions, thereby generating added savings in cost and embodied carbon. CALMFLOOR would represent a game-changing, elegant floor vibration solution that would meet vibration performance without any additional, unnecessary materials.